Photocell sensor installation tip

Advice from the Experts: Industrial Gate Safety

Safety as a condition to be sought with relentless fervour is something that is drilled into us from the moment we take our first apprehensive breaths in this world. Our parents go to great pains to ensure that we do not give in to temptations such as bear-baiting, shark-romancing and impromptu chainsaw juggling (spoilsports). I remember when I was still in primary school the teachers used to show us public service videos on road safety for kids featuring an anthropomorphic cat taking disturbingly trusting children by the hand and leading them across the road.

Of course, in the grown-up world, there is no helpful wildlife to guide us on our path and we are left to mostly fend for ourselves. But even without the aid of Mr Pedestrian Safety Cat or whatever his name was, we still inherently know that safety and self-preservation are things which are desirable.

Safety is something we take extremely seriously at Centsys, and that is why we actively promote the use of some sort of protective device with all automated gate installations. Infrared gate safety beams are universally considered to be the most effective automated gate safety ancillary, winning out in terms of reliability as well as cost-effectiveness.

On high-volume industrial-type sites where the gates are heavy and the traffic even heavier, safety is an integral part of the automated system but does in some instances require some modification. To cater for vehicles of variable heights, many installers opt to fit two sets of infrared beams vertically so that both larger, heavy-duty vehicles such as trucks and normal-sized vehicles will break the beam that prevents the gate from closing onto them.

We frequently get asked what the optimal configuration for the beams is, and in this article, one of our resident technical geniuses provides us with the answer.

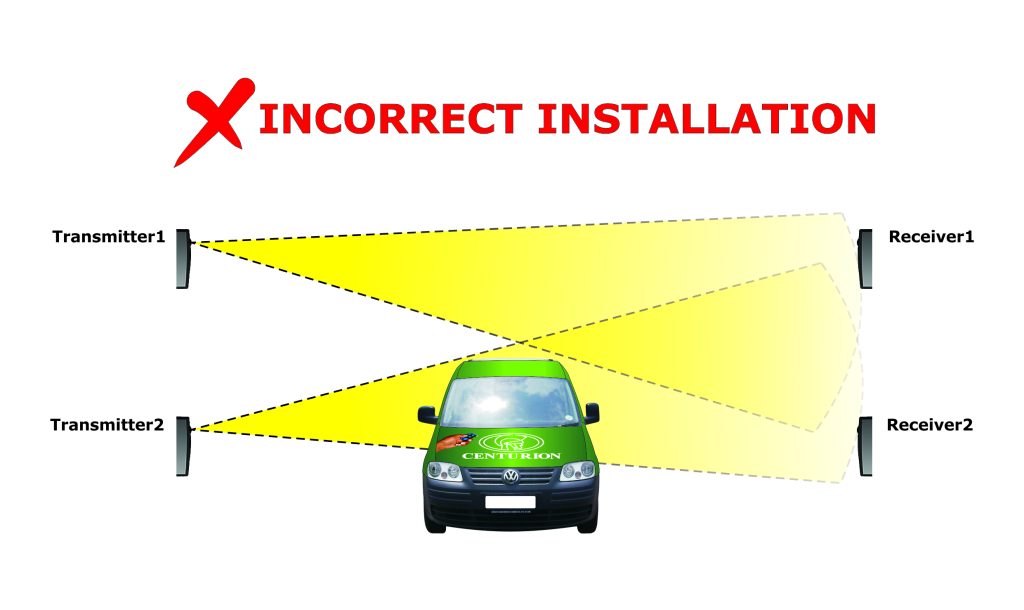

According to senior support technician, Joel Nkuna, it is preferable to mount the beams in a criss-cross or ‘x’ configuration, with transmitter and receiver for beam set 1 facing each other, and the positions of the modules reversed for the second beam set. This, says Joel, is to avoid a situation where the wide beam cast by one transmitter is ‘picked up’ by both receivers (which would be the case if they are both mounted on the same side of the entrance or exit), in which case an object would have to obscure both beams simultaneously for the system to have the desired effect.

Historically, performing this type of ‘juxtaposed’ beam installation has been a bit of a commissioning nightmare due to the extensive wiring that it requires, but the availability of products such as CENTSYS’s Photon infrared beams – which boast a wireless transmitter – has greatly simplified installation and makes it easy for installers to achieve maximum gate safety in industrial applications.

With thanks to the immensely talented Andre from our DTP department for providing me with the most excellent illustrations showing the different installation configurations.